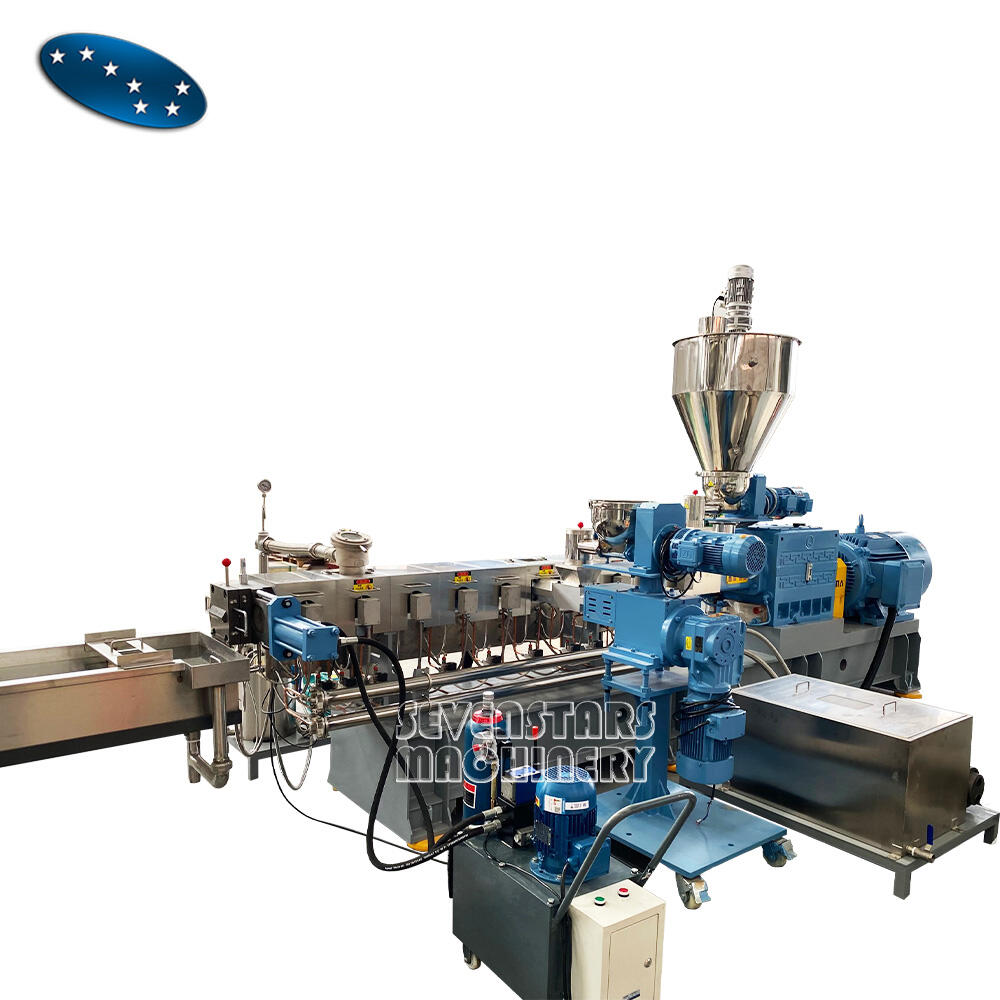

Introducing, the Wasted Plastic PET bottle flakes recycling Pelletizing machine Parallel twin screw Granulator line, a top-quality recycling solution that is sure to blow your mind! This innovative and eco-friendly product is designed to transform used plastic PET bottle flakes into high-quality pellets, which can then be used to manufacture a wide range of new plastic products.

Manufactured by SEVENSTARS MACHINERY, this recycling machine is designed to handle large volumes of plastic waste efficiently and effectively, making it the perfect solution for businesses looking to reduce their environmental footprint. Powered by a robust and reliable parallel twin screw Granulator, this machine is capable of processing a wide range of plastic materials, including PET, HDPE, and LDPE.

One of the most impressive features of this machine is its highly efficient screw design, which ensures consistent and reliable performance even under high loads. Working in tandem with a powerful motor, the parallel twin screw Granulator is capable of producing high-quality pellets at a rate of up to 1000kg per hour.

In addition to its impressive performance, this recycling machine is also remarkably easy to use and maintain. Featuring a user-friendly control panel and intuitive interface, operators can quickly and easily adjust the machine settings to meet their specific needs. Additionally, the machine comes equipped with a series of safety features, including emergency stops and safety guards, to ensure reliable and safe operation at all times.

Whether you're looking to reduce your environmental impact, save money on manufacturing costs, or simply streamline your production process, the Wasted Plastic PET bottle flakes recycling Pelletizing machine Parallel twin screw Granulator line from SEVENSTARS MACHINERY is the perfect solution for your business needs. So, why wait? Contact us today to learn more about this powerful and sustainable recycling solution

PET bottle flakes recycling Pelletizing machine

Plastic Pelletizing Granulator machine is used to recycle various kinds of plastic products and make plastic into granules to recover the plastic and suit for making products againThe the strands go into the Pelletizer automatically by the water flow, even the strands break during changing the filter. so there will be almost no waste during the manufacturing process. If the strand number more than 25 pieces (the output about 80okg/h), it will be more difficult for operator to handle the hot strand to Pelletizer manually

The component characteristics of the water Granulation production line are mainly reflected in the high efficiency of cutting components, the cooling and shaping effect of the water circulation system, the convenience of the automation control system, the durability of wear-resistant components, and the energy-saving measures of thermal insulation

The water Granulation production line has the characteristics of high efficiency, environmental protection, adjustable particle size, low noise, simple operation, and wide applicability. With the continuous innovation and development of technology, water Granulation production lines will be applied in more fields

Parallel twin-screw

The parallel twin-screw structure adopts two coaxial parallel rotating screws, which move along a common axis through interlocking rotation to achieve material conveying

Water cooling system

Use a water circulation system to cool and shape the cut particles. The water ring or flow formed by high-speed water injection can quickly take away heat, causing it to quickly cool and solidify into the desired shape

Cutting unit

The high-speed rotating blades of cutting components can quickly and accurately cut raw materials into particles of the desired length. The material and design of the blade need to have high wear resistance and high cutting efficiency to cope with materials of different hardness and viscosity

| Model |

Screw Diameter |

Screw L/D |

Second Screw L/D |

Main Motor Power |

Capacity |

| SHJ85 |

85mm |

28-33:1 |

10-12:1 |

55KW |

150-200kg/hr |

| SHJ100 |

100mm |

28-33:1 |

10-12:1 |

75KW |

200-300kg/hr |

| SHJ130 |

130mm |

28-33:1 |

10-12:1 |

90KW |

300-400kg/hr |

| SHJ150 |

150mm |

28-33:1 |

10-12:1 |

110KW |

400-500kg/hr |