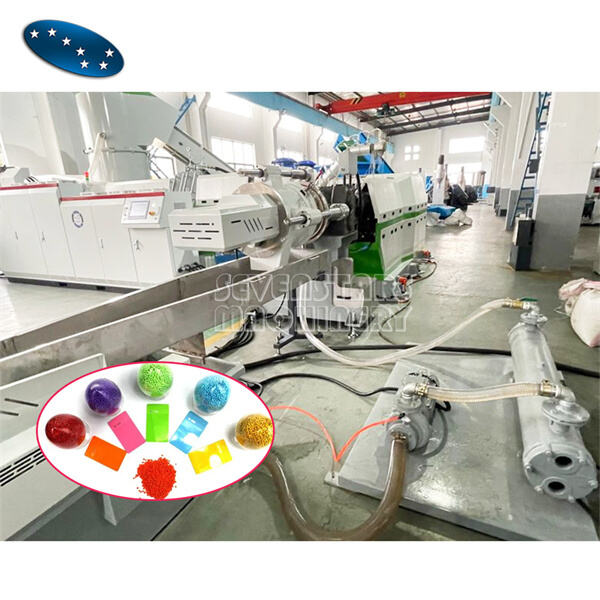

The phrase “parallel twin screw” has a certain sci-fi ring to it. But what it is, really, is a kind of technology employed in machines that make things like plastic products. At SEVENSTARS MACHINERY we can produce countless products from parallel twin screw extruders. These machines have two screws that rotate side by side. This mixes and pushes materials through the machine to form them into new things.

A real upside of parallel twin screw extruders, for instance, is that they are great at mixing. That makes it possible for them to blend various sorts of stuff together very well, and this, in turn, is super important for making good products. Also these machines can handle high volumes of material, so they can produce a lot of products at once.

Parallel type twin screw design at SEVENSTARS MACHINERY make the compounding well. What that means is that the materials mix together more uniformly. This is a big deal when you need to ensure that every single part of your product is of equal quality and strength.

These machines can not only mix well; they move quickly as well. This contributes to boosting the daily rate that can be produced. The more production, the faster we can meet the needs of our customers, which is always a net positive.

Parallel Twin Screw Extruders are not a one-size-fits-all type of machine. They can be employed in a variety of industries to make pipes, sheets and other plastic products. This flexibility also makes them a key instrument to many companies.

Another thing that is of importance about these machines is that the produce is very consistent. Which is to say, every product they make is high quality. Customers rely on us because they know that everything they purchase from SEVENSTARS MACHINERY is going to be high quality.

Finally, for the large volume buyer, these extruders are an economical alternative. Not only do they crank out a lot of products, fast, but they are good at using materials efficiently — and keeping costs down. This reduces the amount of effort needed for wholesale buyers to get a fair deal in buying from us.

With over 20 years of expertise in plastic extrusion and recycling machinery, we have grown into a medium‑sized, internationally recognized supplier, exporting to more than 150 countries worldwide and earning a strong reputation for reliability and innovation.

Our experienced after‑sales team provides installation, commissioning, and long‑term maintenance services, ensuring smooth equipment operation, while ongoing R&D keeps our technology at the forefront of the plastic machinery industry.

Operating from a 200,000‑square‑meter workshop with a skilled workforce of 100+, we manufacture a full portfolio of plastic recycling lines, extrusion systems, shredders, pulverizers, and auxiliary equipment to meet diverse industrial needs.

We implement strict quality management from raw materials to finished products, supported by precision testing and a dedicated QC team, while offering tailored machinery solutions designed to fit specific customer applications and production requirements.

Copyright © Zhangjiagang Sevenstars Machinery Co.,Ltd. All Rights Reserved Privacy Policy Blog