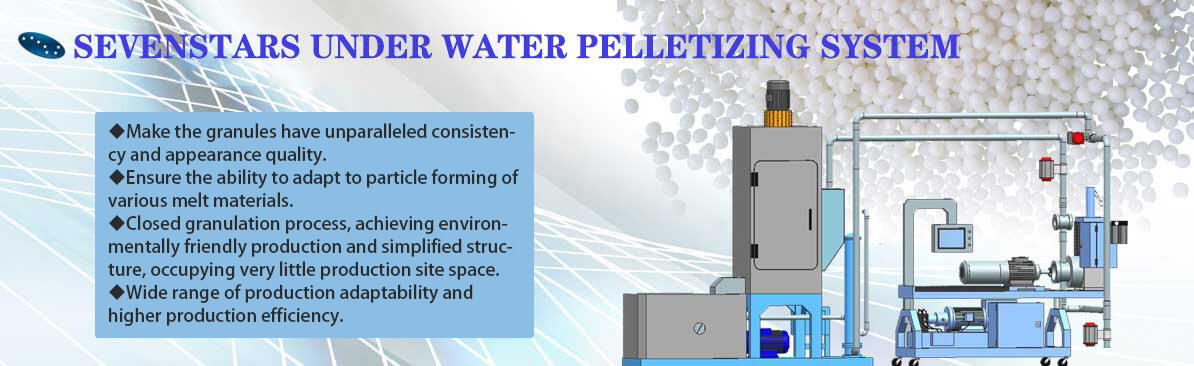

SEVENSTARS MACHINERY is pleased to offer its latest innovation for plastic processing – the TPE/EVA/PP/TPR underwater Pelletizing machine Granulating machine Granulator Recycling line. This state-of-the-art equipment is designed to efficiently and effectively recycle plastic waste and produce high-quality pellets suitable for a variety of industrial applications.

The TPE/EVA/PP/TPR underwater Pelletizing machine Granulating machine Granulator Recycling line is characterized by its simple operation, low maintenance, and high efficiency. Equipped with cutting-edge technologies and top-quality materials, this equipment delivers robust performance, reliability, and durability. Whether you are processing a small or large volume of plastic waste, the TPE/EVA/PP/TPR underwater Pelletizing machine Granulating machine Granulator Recycling line is up to the task.

The TPE/EVA/PP/TPR underwater Pelletizing machine Granulating machine Granulator Recycling line features a cutting system that ensures consistent and precise sizing of plastic pellets. The underwater pelletizer mechanism maximizes pellet quality by eliminating strand breakage and minimizing dust and heat generation. This results in pellets that have uniform shape, size, and density, ideal for injection molding, extrusion, and other applications.

The TPE/EVA/PP/TPR underwater Pelletizing machine Granulating machine Granulator Recycling line is also equipped with advanced safety features that ensure user protection and promote equipment longevity. The system is designed with several sensors and control mechanisms that notify users of any faults or malfunctions. Furthermore, the machine's control panel is designed to be easily accessible, allowing technicians to quickly diagnose and address any issues that may arise.

SEVENSTARS MACHINERY's TPE/EVA/PP/TPR underwater Pelletizing machine Granulating machine Granulator Recycling line is a comprehensive solution for plastic processing that enables minimal downtime and maximum production efficiency. The equipment is suitable for processing a wide range of plastic materials, including thermoplastics such as polyethylene, polypropylene, and polystyrene, and thermoplastic elastomers like TPE and TPR.

If you operate a plastic recycling business or are in the process of starting one, consider investing in the TPE/EVA/PP/TPR underwater Pelletizing machine Granulating machine Granulator Recycling line from SEVENSTARS MACHINERY. This innovative equipment will not only save you money in the long run but also help you transform plastic waste into high-quality, marketable pellets that meet your clients' needs. Choose SEVENSTARS MACHINERY and achieve sustainable and profitable plastic recycling operations

Underwater Pelletizing Machine

New Pelletizing machine which is in the moment of melt pump extrusion to touch with the cold water, then cut directly. Melting Pelletizing has some obvious advantages compared with solidifying Pelletizing. Advanced twin screw extruder characterized by high efficiency mixing combined with low energy consumption per kg output. The underwater pelletizer cuts polymer strands into pellets immediately after they have passed the die plate. Applied to EVA, TPU, TPR, PP Non-woven Bag plastic granules making has excellent mixing performance, good self-cleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of material

To melt and filter the plastic adopting the single extrusion or twin screw extrusion the strand or hot face cutting system to produce the granules, finally cooling or solidified to cut

Advantages:

1. For plastic being cut off in melting status, then solidification through circulation water. So different viscosity high polymers all can adopt this cutting type. There is no any dust, shape structured, easy package and transport in melting to cut plastic granules2. It can change the size and shape as per the extrusion rate and cutting speed to adopting different die heads. It also can use different Qty of knife to change the size and shape of plastic granules

3. The cutting plastic granules and cooling system are in one combined which saves the 4~6mm water tank, reduces the area of floor space

4. This technology realizes automatic production, easy to operate, low noise, good granules quality

5. Bigger capacity than water strand, lower power

Model |

Power |

Capacity(kg/h) |

SHJ-50 |

55 |

100-300 |

SHJ-65 |

90 |

250-400 |

SHJ-75 |

150 |

300-1000 |

SHJ-95 |

300 |

800-2000 |