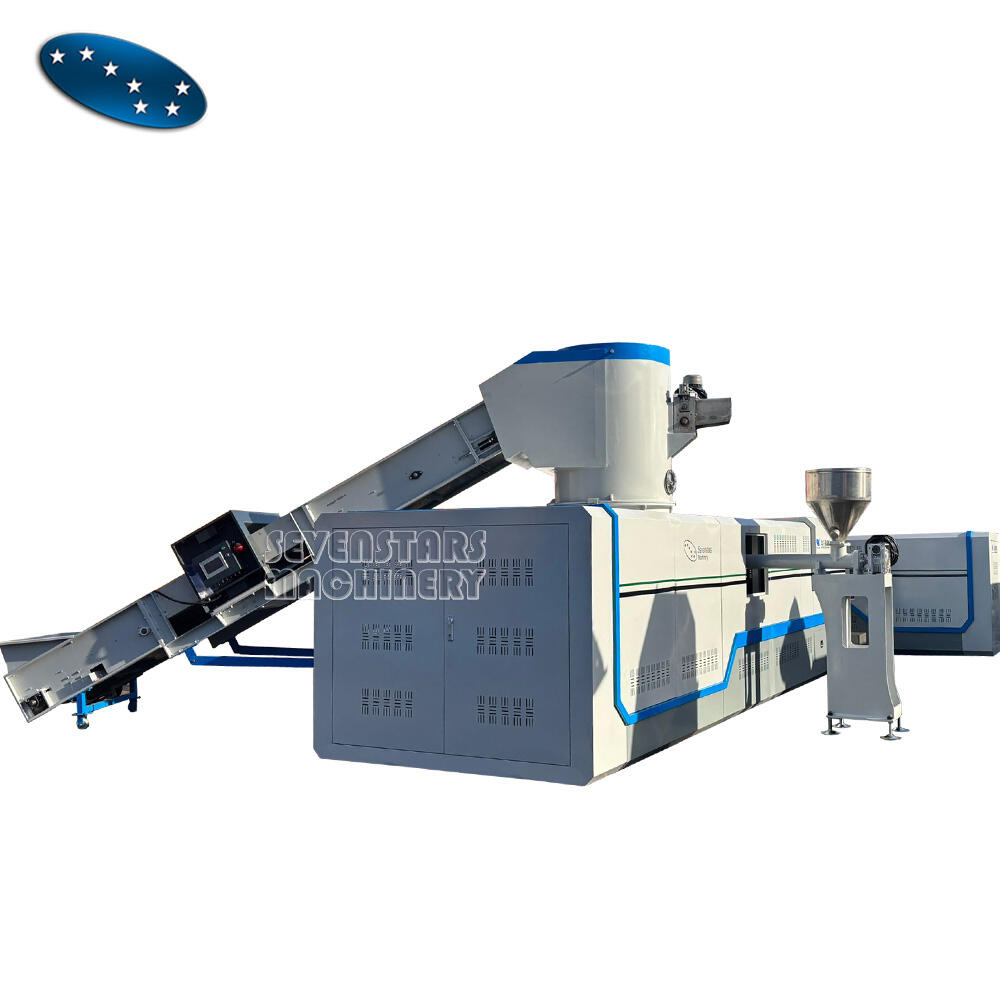

If you're in the market for a top-notch plastic Pelletizing machine, you should definitely check out the Sevenstars Machinery’s wet material plastic film bags Granulator line. This is a top-of-the-line plastic recycling machine that is sure to meet all of your requirements and more. Here is a closer look at this amazing product.

The Sevenstars Machinery’s Plastic Pelletizing Machine is a must-have for any business that deals with plastic. This machine is the ultimate solution to recycling plastic waste, whether it's from production or post-consumer use. The entire machine is designed to granulate and Pelletize plastic materials, whether they're rigid or flexible, into high-quality pellets that can be used for numerous applications. This advanced device is designed to recycle old plastic bags and re-purpose them into new plastic products. So, making raw materials readily available for the production of new products.

One of the unique selling points of the Sevenstars Machinery’s Plastic Pelletizing Machine is its ability to handle wet materials. The machine is equipped with a state-of-the-art drying system that ensures that even wet materials are processed efficiently, ensuring optimal performance and energy savings. This also makes the machine highly versatile, enabling it to handle a wide range of applications.

The Sevenstars Machinery’s Plastic Pelletizing Machine is also a highly automated machine. The machine is designed to minimize human intervention as much as possible, which means that you can operate it with minimal risk of damage or errors. The machine's precision control system ensures that it operates at optimal capacity, so you get the best possible output.

When it comes to energy efficiency, the Sevenstars Machinery’s Plastic Pelletizing Machine is second to none. This machine is designed with energy-saving features that ensure that you save on your energy bills. This is an important consideration, especially in today's green-conscious environment.

Finally, you can rest assured that when you buy the Sevenstars Machinery’s Plastic Pelletizing Machine, you're investing in a high-quality product that's built to last. This machine is constructed with high-quality materials and is designed to withstand harsh operating conditions. What's more, the after-sales support offered by Sevenstars Machinery is among the best in the industry.

If you're looking for a high-quality plastic Pelletizing machine that guarantees optimal performance and efficiency, the Sevenstars Machinery’s Plastic Pelletizing Machine is the ideal choice for you. This machine is designed to handle all sorts of plastic materials, including wet materials and is guaranteed to provide the best return on investment. So, why wait? Order your Sevenstars Machinery’s Plastic Pelletizing Machine today and experience the benefits of modern recycling technology

Plastic Wet Material Film Bags Granulator Machine

Advantages of this plastic Pelletizing machine :

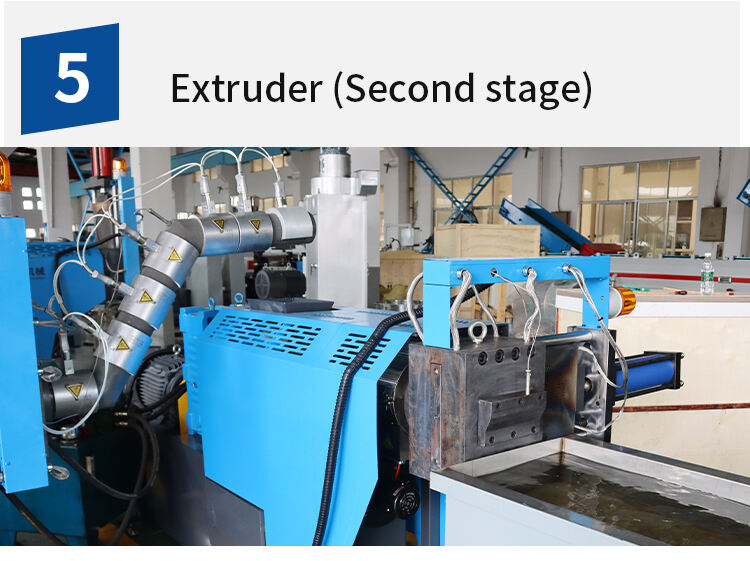

PE/PP recycling granulating machine is special equipment for the PE PP film recycling granulating, it equipped with compacting machine which pre- compact the film into smaller granules, then easily feed into screw barrel of extruder, its efficiency is high and can improve production capacity and save labour cost

It has two vacuum exhausting mouth on extruder barrel which can fully vent the moisture in the material and hence the final granule quality will be very perfect

At the end of screw barrel, it equipped with double post fast speed hydraulic non -stop screen changer which can effectively fit out the dirty in the plastic melt. the Pelletizing adopts water flush Pelletizing which is easier to operate, and the shape and appearance of granule is good

Specification

The First Stage Extrusion Machine

| Model |

Screw Dia/MM |

Screw Length/MM |

Venting Way |

Main Motor Driving Power/KW |

Heating Area Qty/pcs |

Heating Power/KW |

Capacity/KG/H |

| SJ-160 |

158 |

2800 |

Single |

55 |

5 |

50 |

180-350 |

| SJ-200 |

197 |

3500 |

Single |

90 |

7 |

162 |

400-650 |

| SJ-280 |

277 |

4000 |

Single |

132 |

10 |

180 |

500-800 |

The First Stage Extrusion Machine

| Model |

Screw Dia/MM |

Screw Length/MM |

Venting Way |

Main Motor Driving Power/KW |

Heating Area Qty/pcs |

Heating Power/KW |

| SJ-160 |

150 |

1500 |

NO |

30 |

5 |

25 |

| SJ-200 |

197 |

1600 |

NO |

45 |

5 |

27 |

| SJ-280 |

277 |

1800 |

NO |

55 |

5 |

50 |

The First Stage Extrusion Machine

| Model |

Screw Dia/MM |

Screw Length/MM |

Venting Way |

Main Motor Driving Power/KW |

Heating Area Qty/pcs |

Heating Power/KW |

| SJ-150 |

150 |

1400 |

NO |

22 |

5 |

23 |

| SJ-180 |

177 |

1600 |

NO |

45 |

5 |

27 |

| SJ-260 |

257 |

1800 |

NO |

55 |

5 |

45 |