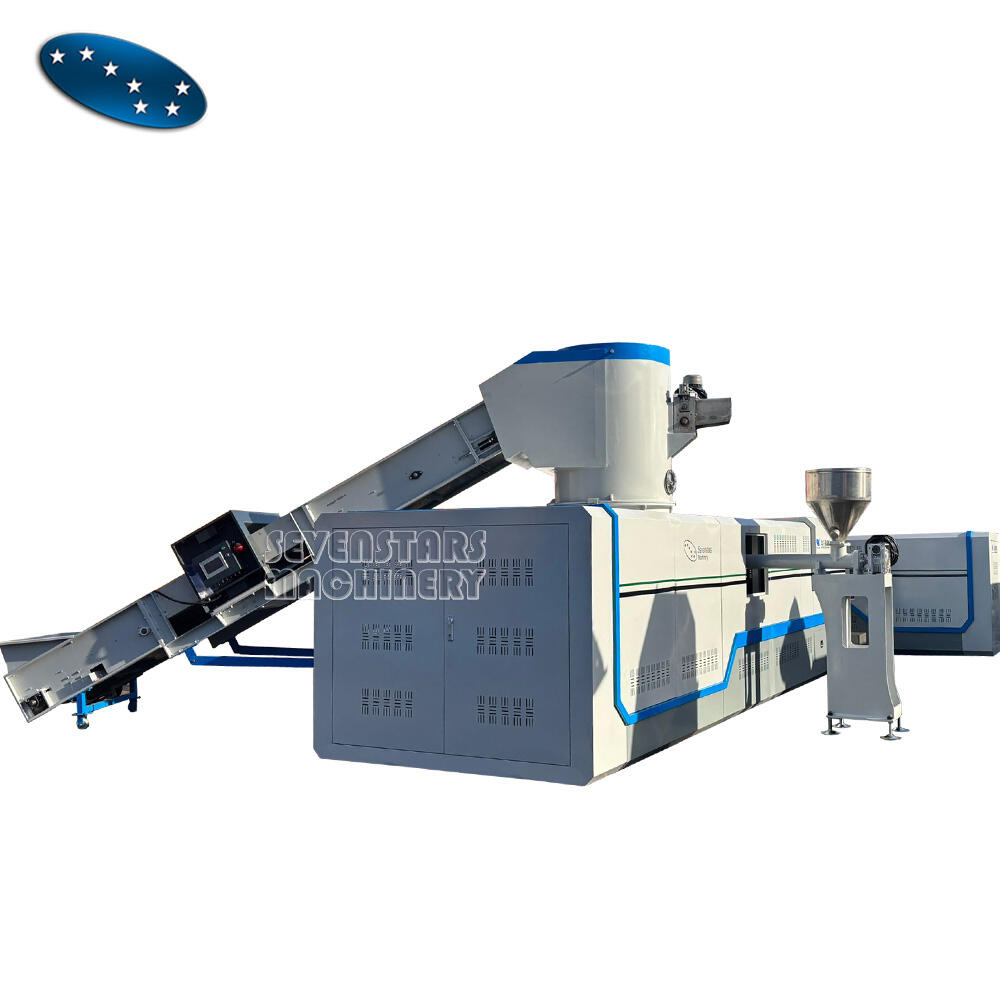

Introducing, the SEVENSTARS MACHINERY’s Cable Soft PVC Parallel Double Screw Pelletizer Material Pelletizing Machine Parallel Screw Extruder - a versatile and effective solution for all your material Pelletizing needs!

This high-quality machine is made from premium grade materials and features a robust design that ensures its longevity and durability. The double screw design ensures efficient and consistent Pelletizing, delivering high quality pellets every time.

With its easy to use interface, this machine is perfect for both beginners and experts alike. It features a large, touch screen control panel that allows you to easily set and adjust all the relevant parameters, such as temperature, speed, and pressure. You can also monitor the machine's performance in real-time, thanks to the clear and intuitive display.

The SEVENSTARS MACHINERY’s Cable Soft PVC Parallel Double Screw Pelletizer Material Pelletizing Machine Parallel Screw Extruder can process a wide range of materials, including soft PVC, HDPE, LDPE, PP, and more. This makes it ideal for various industries, such as plastics, packaging, and rubber.

The machine's parallel screw extruder ensures a uniform and efficient melting process, allowing for consistent and high-quality pellets every time. Additionally, the machine's compact design and small footprint make it perfect for use in smaller spaces, making it an ideal choice for businesses of all sizes.

Finally, the machine's maintenance and cleaning are easy thanks to its robust construction and removable parts. The clean operation ensures that the machine remains hygienic and well-maintained, reducing the risk of contamination and ensuring it lasts for years to come.

The SEVENSTARS MACHINERY’s Cable Soft PVC Parallel Double Screw Pelletizer Material Pelletizing Machine Parallel Screw Extruder is an affordable, high-quality, and reliable solution that is perfect for all your material Pelletizing needs. With its versatility, ease of use, and robust construction, this machine represents an excellent investment for any business looking to improve its performance, quality, and output. Don't hesitate, get yours today

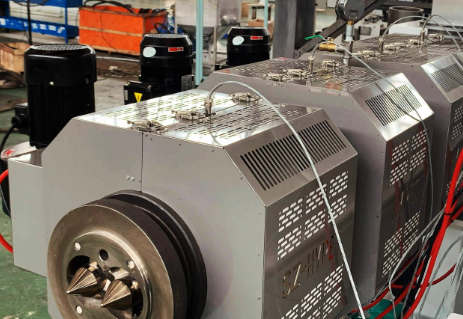

Detailed Images

Parallel twin screw and barrel: This product category refers to the combination of parallel twin screws and the corresponding barrel designed for processing a wide range of materials. The parallel twin screws are characterized by their side-by-side arrangement, which allows for efficient material conveying, melting, and mixing. The barrel is specifically designed to accommodate the parallel twin screws and provide the necessary processing conditions for various applications, including compounding, extrusion, and reactive processing

Feeder

Special anti blocking design

Heaters & blowers

Energy saving type heaters and low noisy blowers

Specification

Model |

SJP75/28 |

SJP95/38 |

SJP110/28 |

SJP120/26 |

SJP130/26 |

Motor power |

37 |

55 |

75 |

110 |

132 |

Screw diameter |

75 |

93 |

110 |

120 |

130 |

Max rotation speed |

76 |

36 |

35.8 |

34.3 |

34.3 |

L/D Ratio |

28:1 |

28:1 |

28:1 |

26:1 |

26:1 |

Max output |

240 |

380 |

460 |

550 |

680 |

Weight |

4100 |

4700 |

6500 |

7500 |

8400 |