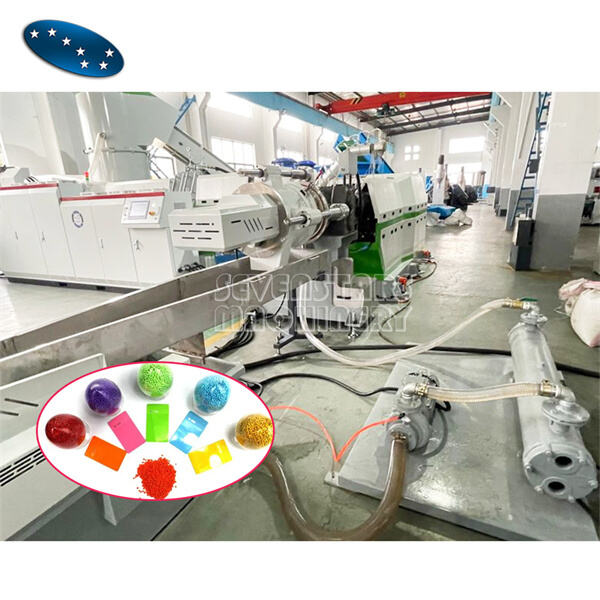

This machine is called a parallel twin screw extruder, and it is used to produce different products by means of passing materials through two screws which run parallel. It is commonly used in various industries like in food processing, pharmaceuticals and plastic manufacturing. They are necessary for the making of products such as PVC piping and tablets.

In a parallel twin screw extruder, material is fed into the machine through a hopper on one end. The result is these materials are processed within the screws, which turn in opposite directions. The materials are fed through the extruder, heated and mixed to create a homogeneous material.

Parallel twin screw extruder made of two screws that could be adjusted to apply pressure and heat to the materials being processed. Through this customization, one can conveniently define the parameters based on which they want their products to possess properties such as texture and density.

So, what things matter the most or are to give consideration for it while selecting a parallel twin screw extruder and making a purchase with your company. Examples include the size of the extruder, screw speeds and heating options—all of them should be considered in your decision.

For instance, if you have to handle huge quantities of material with a high through put rate, you may consider utilizing high velocity screws in a parallel twin screw extruder. Conversely, you might choose an extruder that heats up more quickly by maintaining a higher temperature if you are working with materials that are more sensitive to changes in temperature but need the precision.

The problem with parallel twin screw extruders is that they behave like any machine and may develop certain glitches that cause them to underperform. Overheating, screws blocking and uneven blending of the material are some common issues faced. This makes it even more important to properly maintain and clean your extruder, on a regular basis.

The first thing you need to do when something goes wrong with your parallel twin screw extruder, is check the screws if they are clogged. This will ensure that the materials slide through all extruder pathways with ease. It also may be that you should keep an eye on the temperature of the machine and pick gums as that would avoid overheating and making sure your products are being produced ideally with the right produces.

Our experienced after‑sales team provides installation, commissioning, and long‑term maintenance services, ensuring smooth equipment operation, while ongoing R&D keeps our technology at the forefront of the plastic machinery industry.

We implement strict quality management from raw materials to finished products, supported by precision testing and a dedicated QC team, while offering tailored machinery solutions designed to fit specific customer applications and production requirements.

Operating from a 200,000‑square‑meter workshop with a skilled workforce of 100+, we manufacture a full portfolio of plastic recycling lines, extrusion systems, shredders, pulverizers, and auxiliary equipment to meet diverse industrial needs.

With over 20 years of expertise in plastic extrusion and recycling machinery, we have grown into a medium‑sized, internationally recognized supplier, exporting to more than 150 countries worldwide and earning a strong reputation for reliability and innovation.

Copyright © Zhangjiagang Sevenstars Machinery Co.,Ltd. All Rights Reserved Privacy Policy Blog